SynergX Curve inspection system family for bent glass

The Curve family of glass inspection systems is part of the fully automated zero-defect glass inspection solutions designed specifically for bent glass.

All SynergX Curve systems are designed to be installed inline in the production process, as part of the last and final inspection stage for quality assurance. The Curve systems withstand full production speeds.

While the Curve systems are designed and can be used for a wide range of glass manufacturing applications, they are mainly used in the automotive manufacturing industry.

All Curve systems inspect painted and non-painted glass surfaces. They also provide defect classification. The glass can be of any shape and size, with light transmissivity from 5.6% to 92%. Paint elements, such as paint bands, screen positions, printing borders, logos, and paint openings (including camera and VIN zones), can be inspected for defects. Tolerances for each individual defect can be set to accommodate various quality requirements. A dual model mode enables the inspection of two different glass models in the same production run.

This family of systems is comprised of three models that can accommodate most installations and inspection requirements: Curve 200, Curve 60, and the latest addition, Curve 60 SLIM.

CURVE 200

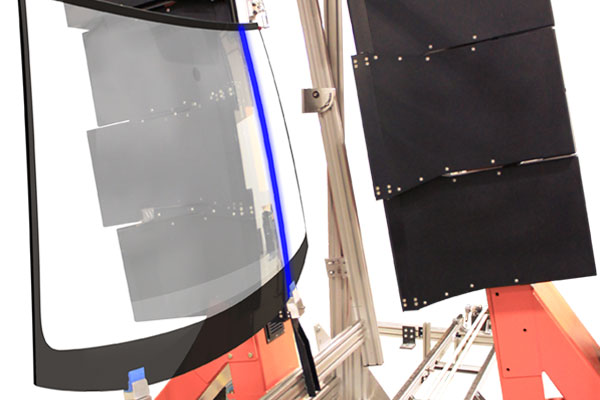

The Curve 200 inspects bent glass with up to 200 mm of depth of bend and up to 1600 mm high glass and 2000 mm long on a vertical conveyor, with a resolution of .110 mm per pixel. Its telecentric Chroma optics and lighting provide a consistent and accurate view of defects, offering high-sensitivity detection of light scratches and edge defects. The Curve 200 integrates into an existing vertical conveyor and has a small footprint on the production line. The Curve 200 is typically used for automotive windshield and backlite inspections.

CURVE 60

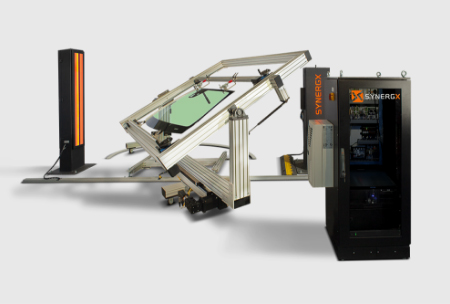

The Curve 60 inspects bent glass with up to 60 mm of depth of bend and up to 800 mm wide and 1200 mm long, with a resolution of .130 mm per pixel. Its telecentric optics and lighting provide a consistent and accurate view of defects, offering high sensitivity detection of light scratches and edge defects. The Curve 60 comprises a horizontal flat belt conveyor for installation within the production line with glasses placed smile down. A side-by-side mode allows for the inspection of two glasses simultaneously. Each glass can be two different glass models or the same glass model. The Curve 60 is typically used for automotive sidelite and quarterlite inspections.

CURVE 60 Slim

The Curve 60 SLIM system is the latest addition to the Curve family. It also inspects bent glass with up to 60 mm of depth of bend and up to 1250 mm wide and 1200 mm long, with a resolution of .100 mm per pixel. Its telecentric optics and lighting provide a consistent and accurate view of defects, offering high-sensitivity detection of light scratches and edge defects. The Curve 60 SLIM integrates into an existing horizontal conveyor with glasses placed smile up or down and has a small footprint on the production line. Each glass can be two different glass models or the same glass model. The Curve 60 SLIM is typically used for automotive sidelite and quarterlite inspections.

With multiple installations worldwide, the CURVE line of products provides bent glass manufacturers the capability to reliably assure glass quality to their end customers and optimize their production yields via process optimization and reduced inspection labour.

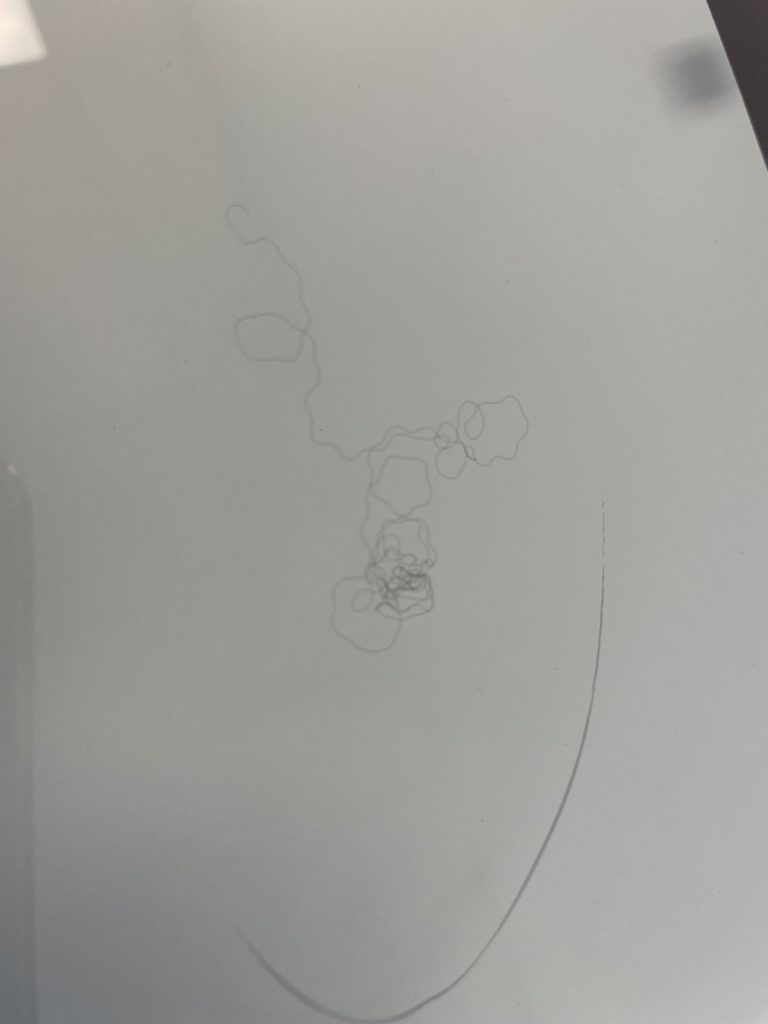

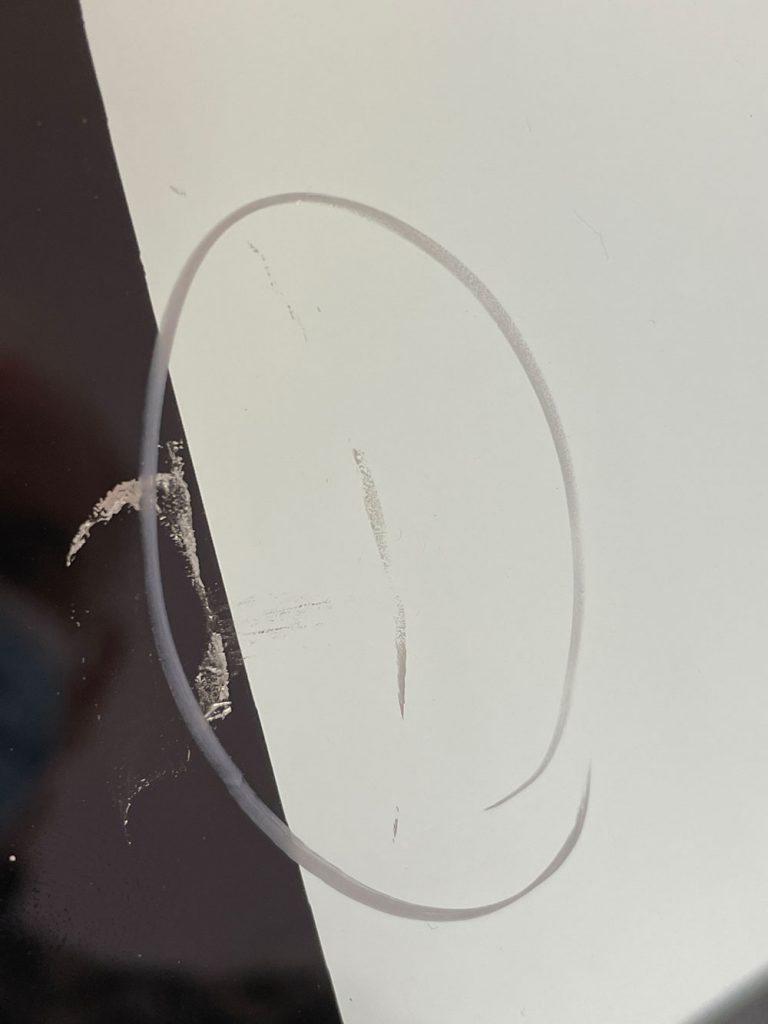

CURVE DEFECTS

About Synergx

World-leading provider of non-contact inspection & metrology solutions designed to optimize glass manufacturing processes.

Did you know? Did you know that Synergx offers a complete and integrated platform for architectural glass inspections?

Learn more about our solutions to elevate the quality of safety glass for architectural applications.