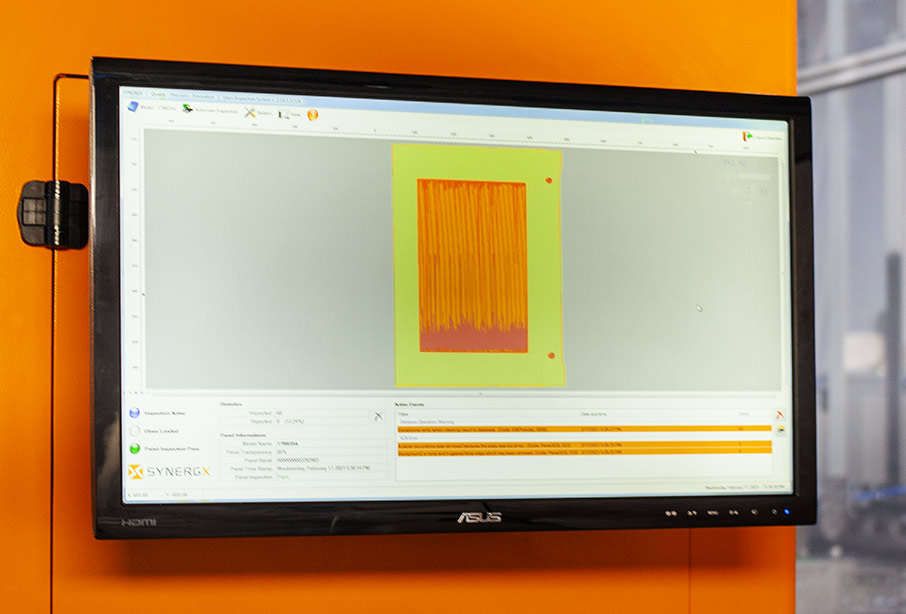

Glass Printing Inspection

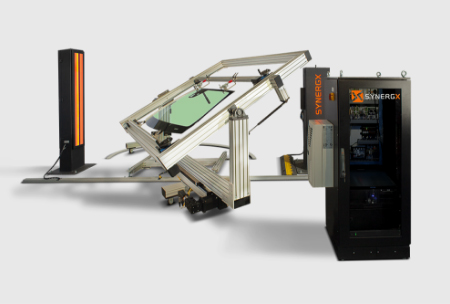

SURFX PAINT

The SURFX PAINT is a family of products providing high quality glass processors with an integrated inline flat glass printing inspection solution meeting the high level required by the OEM Automotive and appliance glass industries

Benefits

Improves product integrity to meet glass manufacturer’s increasingly high expectations

Reduces production costs through waste reduction and productivity improvement

Captures key data for continuous product traceability & process improvement

Convenient footprint and flexible interface allow easy integration into existing production or greenfield project

Features

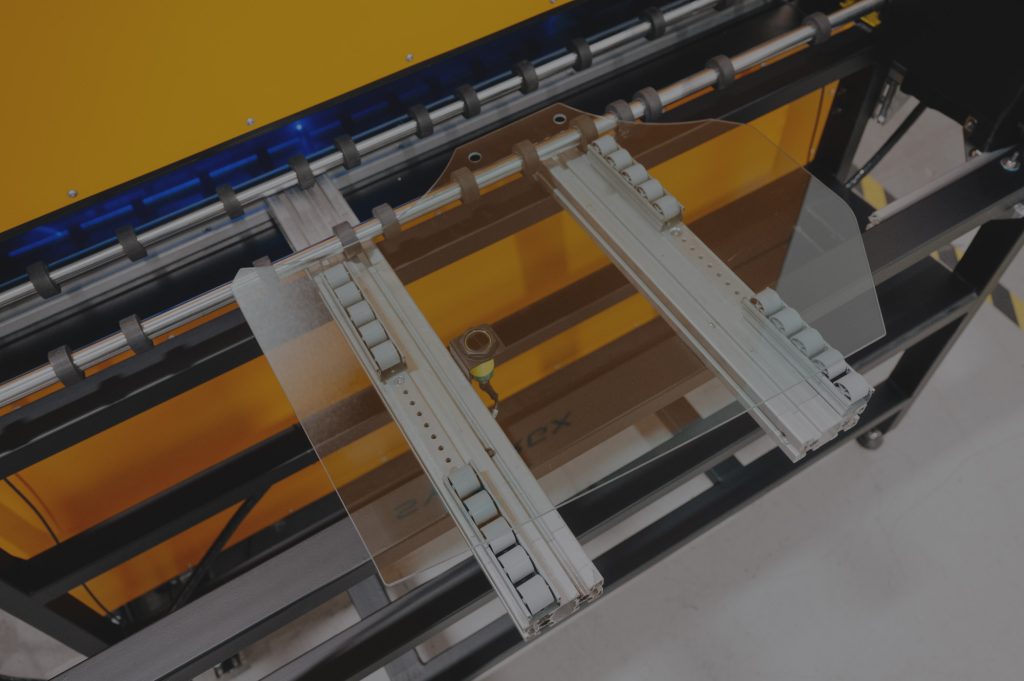

Detection capability

High inspection repeatability & accuracy for glass thickness between 0.75mm and 20mm

Flexibility

Covers all glass shapes & transmissivity

Line integration

Fully integrated to manufacturing processes including product traceability & industry 4.0 platforms

Designed for glass manufacturers that have a wide range of glass type, high volume and fast production cycles and are looking to implement a high standard glass printing inspection system.

The SURFX PAINT inspection system is fully integrated to your manufacturing process and is based on the SYNERGX GI platform

Cédric Marchand,

Head of Quality and Plant QEHS Manager at the SCHOTT flat glass

Call our glass experts to learn about the full comparison between the systems

Send us a request for information and a specialist in your market will contact you.

Other popular products in the glass industry

Welcome to a new era of precision.

Case Study

AGNORA detects architectural glass defects faster thanks to SYNERGX

Discover how SYNERGX contributes to fulfilling AGNORA’s mission to produce impeccable architectural glass!