3D AERO

3D scanner for Jet Engine Combustion Chamber Liner

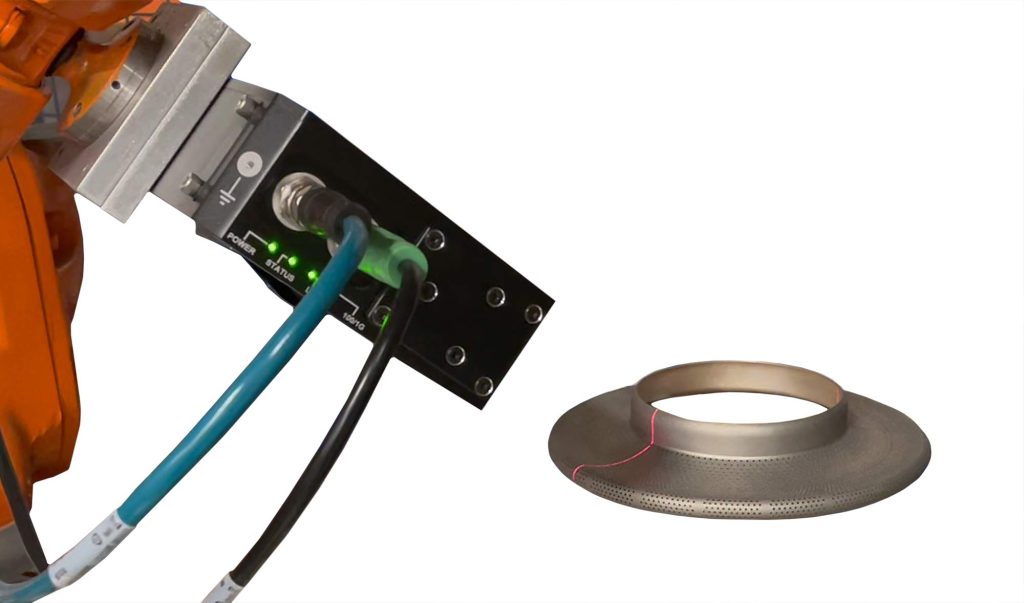

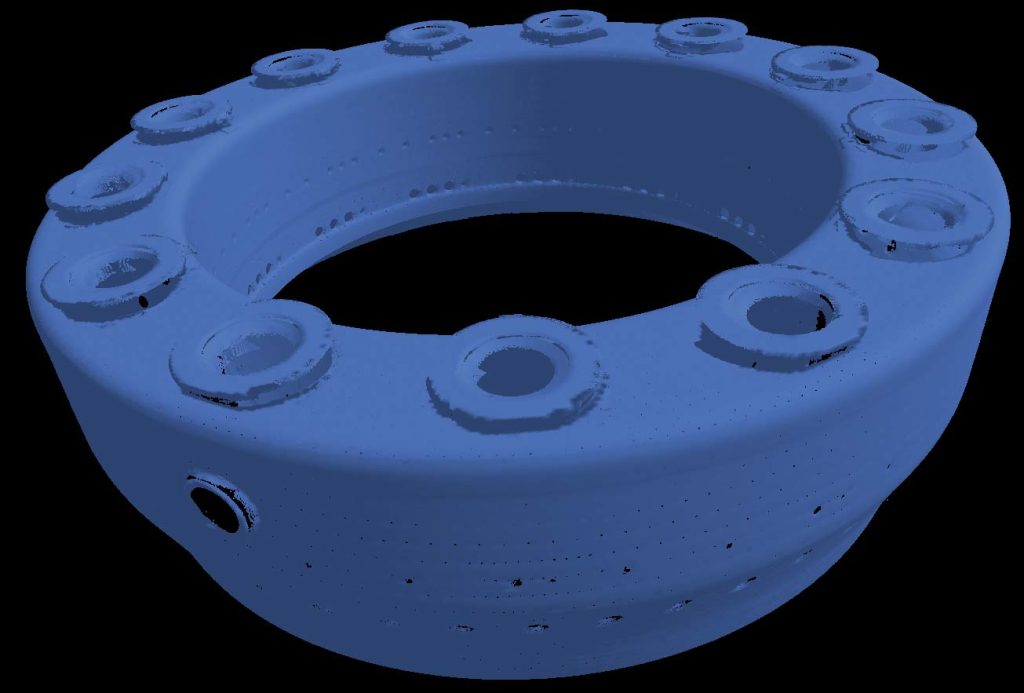

SYNERGX’s 3D AERO is a true, fully automated 3D scanning cell specifically designed to optimize the manufacturing process of jet engine combustion chamber liners. The system performs various measurements like hole measurements and 3D dimensions vs. CAD comparison.

It is available as a standalone system for lab installation or inline system for totally automated 100% inspection on the production line.

The SYNERGX 3D AERO consists of an industrial enclosure, a laser 3D scanner head, a robot arm to position the scanner, a high precision rotating table, and the software to perform all the scans and the measurements required to assure the part’s conformity.

Benefits

Improved quality with 100% 3D scan and inspection without the need to apply special surface coating.

Increased productivity provided by scanning and processing operations in less than 5 minutes.

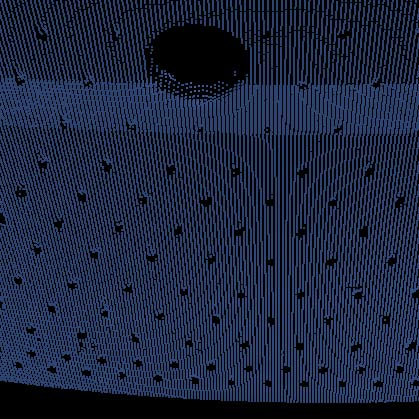

Added control and traceability using software plugins to provide feedback to the hole drilling CNC

Key Features

Available as standalone or integrated to manufacturing lines.

Optimized processing to measure tens of thousands of holes.

User interface for system calibration, parts teaching, scanning and metrology recipe definition.

PLC interface for fully automated integration in production ines.

Volumetric accuracy of 0.025mm.

Contact our experts to learn about the full comparaison between the systems

Send us a request for information and a specialist in your market will contact you.