SYNERGX, an established global leader in automotive glass inspection, is extending its products and expertise to the architectural industry.

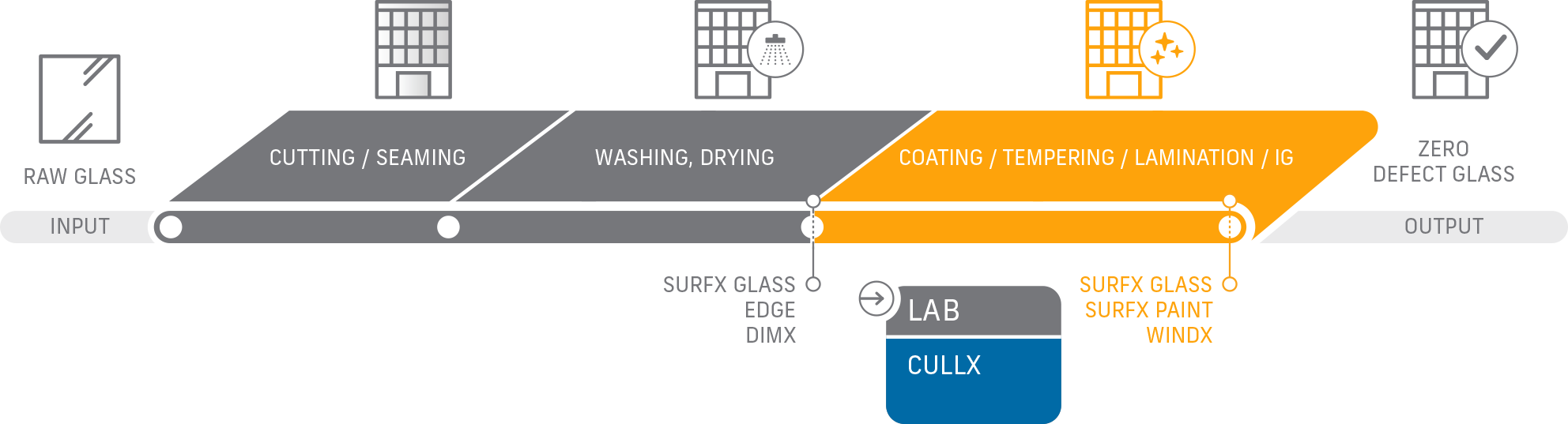

SYNERGX offers a complete and integrated platform for each stage of the glass production process as well as individual systems to address specific inspection challenges.

Architectural Glass Process

Glass Manufacturers deserve the best

With glass requirements for architectural applications becoming increasingly strict, every glass maker needs to implement a strategy and an investment plan to prevent costly mistakes or bad products sent to customers.

SYNERGX, the world leader in non-contact inspection & metrology solutions for the OEM automotive glass is now offering its state-of-the-art technologies to the architectural glass sector.

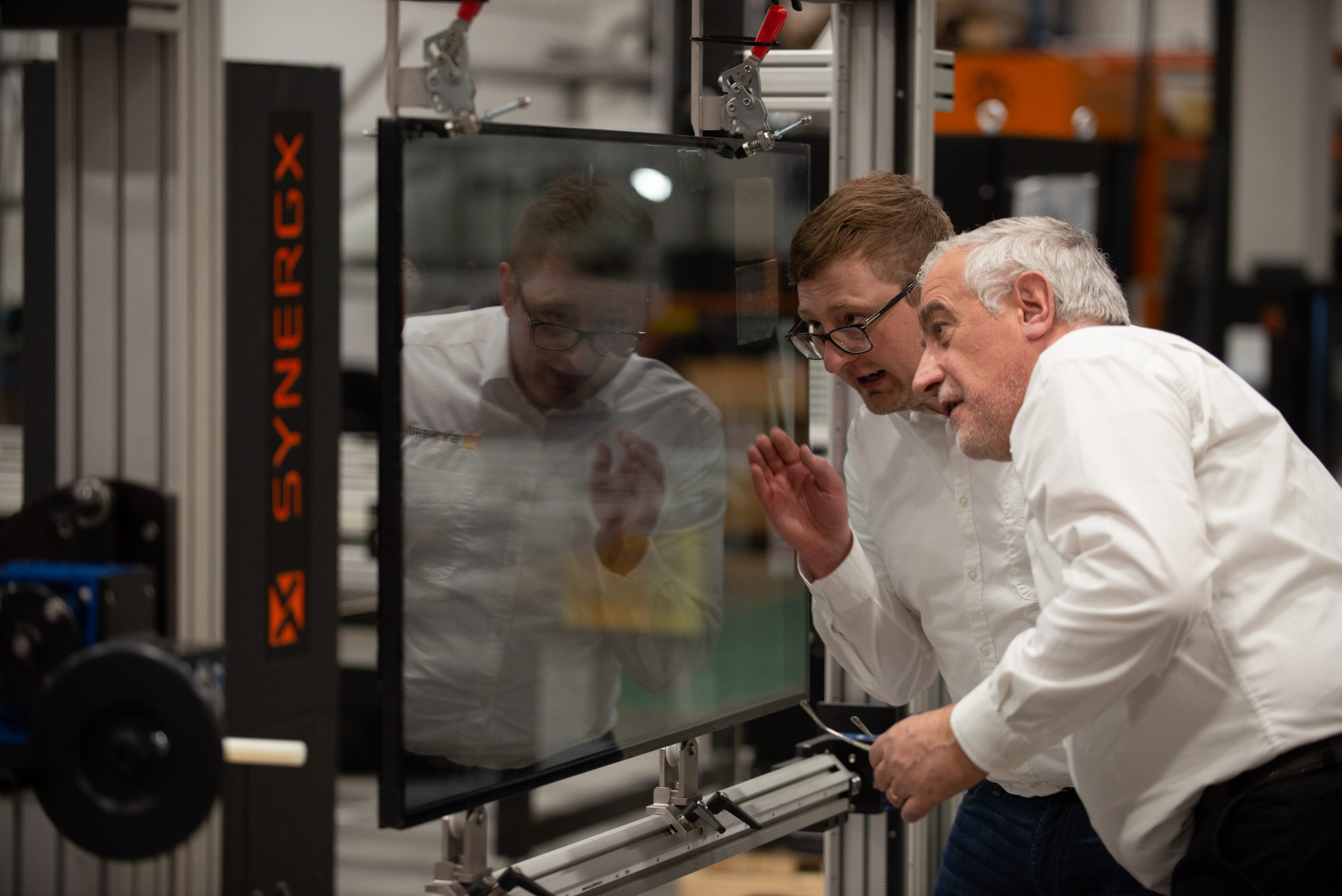

We help you see defects

Case Study

AGNORA detects architectural glass defects faster thanks to SYNERGX

Discover how SYNERGX contributes to fulfilling AGNORA’s mission to produce impeccable architectural glass!

Welcome to a new era of precision

Glass Inspection

SURFX GLASS

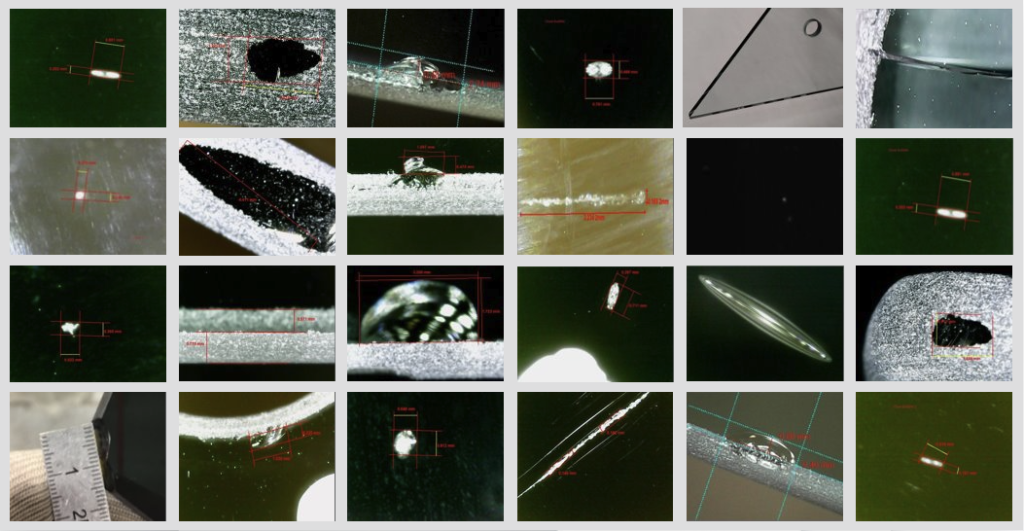

- The SURFX GLASS is an inspection system used following the washing/drying process. It provides high quality glass processors with an integrated inline flat glass inspection solution.

- Complete Inline Flat Glass inspection for architectural glass processes

- IGU lines: pre-assembly or complete unit

- Tempering lines: bed load inspection pre or post tempering

- Lamination lines: pre or post.

Glass Paint Inspection

SURFX PAINT

- Following the painting process, the SURFX PAINT is a fully automated inline inspection system for paint & print inspection on flat glass before or after drying

- Bird friendly patterns, dot patterns, thin lines, bar codes, date code and logo inspection.

Tempered Glass Fragmentation

CULLX

- This inspection system is made for any clear or painted glass to automate the validation process of tempered glass fragmentation based on the architectural industry standards.

- Cullet analysis step of 1.0mm

Grinding Edge inspection

EDGE

- The EDGE system is installed directly after seaming or on bedload prior to tempering furnace. This system is a fully automated inline inspection system for flat glass panels. It is the only continuous movement glass edge inspection system on the market.

- Surface & seaming Inspection

- Supports irregular shapes.

Distortion inspection

WINDX

- The WINDX system is installed at the end of the production line. It is a multi-feature, fully automated non-contact metrology system designed for the characterization of optical properties of glazing.

- Transmissive distortion of glass panels.

Contact our glass expert to learn about the full comparaison between the systems

Send us a request for information and a specialist in your market will contact you.