Automotive Glass Inspection

SYNERGX offers a complete and integrated platform for each stage in the glass production process as well as individual systems to address specific inspection challenges.

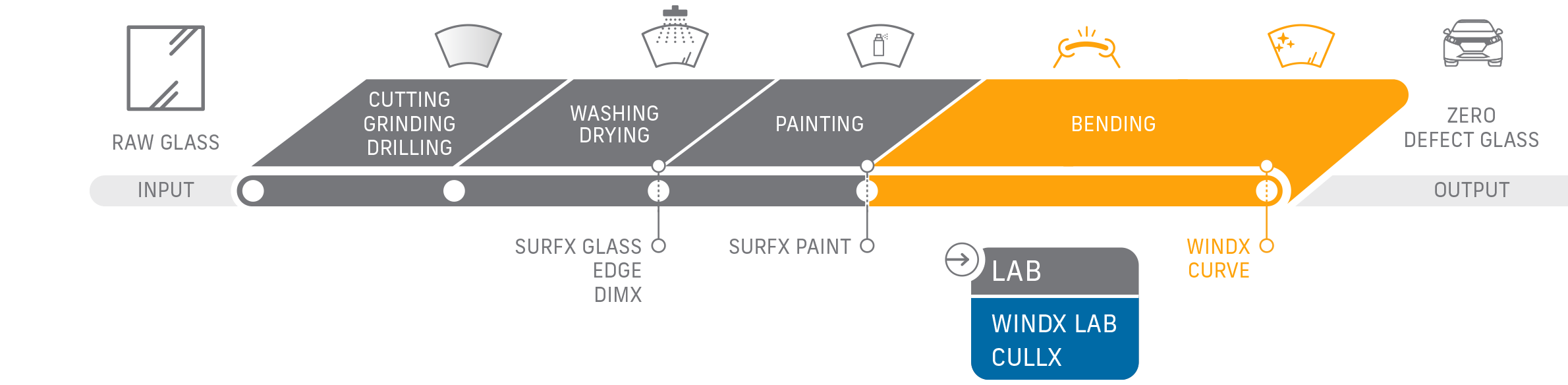

Automotive Glass Process

Glass Manufacturers deserve the best

- Glass manufacturers are under pressure to optimize resources to keep their bottom lines in check

- Internal and external scraps cause tremendous impact on expenditures

- Glass manufacturers need solutions to mitigate costly firewall inspections from OEMs

Typical challenges include:

- Cutting labour costs

- Increasing productivity

- Accelerating production cycles

- Maximizing throughput

Did you know?

Glass manufacturers can see

4 to 10%

of their profits slashed due to defective glass/poor quality products, recalls.

We help you see defects

Welcome to a new era of precision

Don’t compromise on your clients increasingly high expectations. Get rid of slow, error-prone manual inspections now.

Glass Inspection

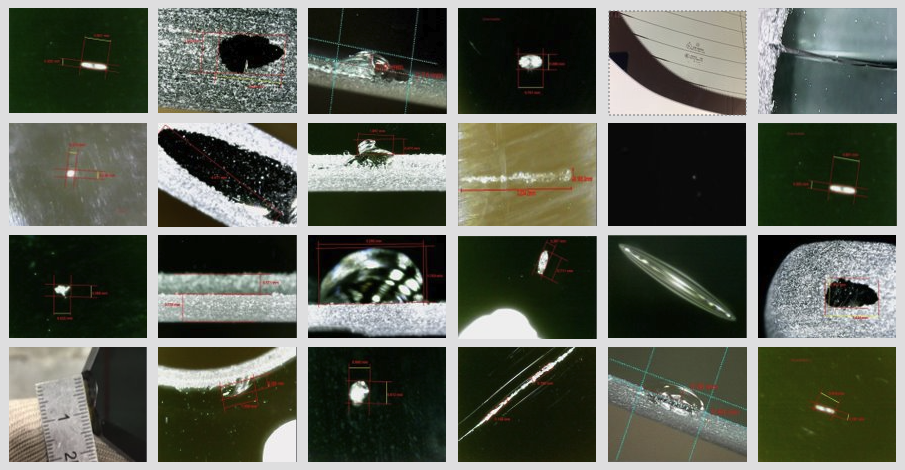

SURFX GLASS

- Raw glass float defects (bubbles, inclusions ...)

- Process defects-damage (scratches, edge chips ...)

- Proprietary Optics for High repeatability to meet automotive industry requirements.

Glass Paint Inspection

SURFX PAINT

- For Paint inspection on flat glass before or after drying

- Fade band, thin lines and logo inspection

- Silver lines inspection

- Glass inspection in the clear area

Grinding Edge inspection

EDGE

- SURFX GLASS and additional grinding process inspection from side view (Shiners)

- 100% continuous inline inspection without stopping or handling the glass

- Supports irregular shapes at automotive glass production speed

Tempered Glass Fragmentation

CULLX

- Cullet analysis step of 1.0mm

- Inspection Latency of 15 secs

- Safety Pedal (Deadman switch)

- IoTX for real time data access

Curved Glass Inspection

CURVE 60

- Automotive sidelites and quarterlites inspection at end of line

- Glass and paint inspection with trasmissive and reflective optics

- 2.3 seconds cycle time in single or dual inspection

- Horizontal conveying

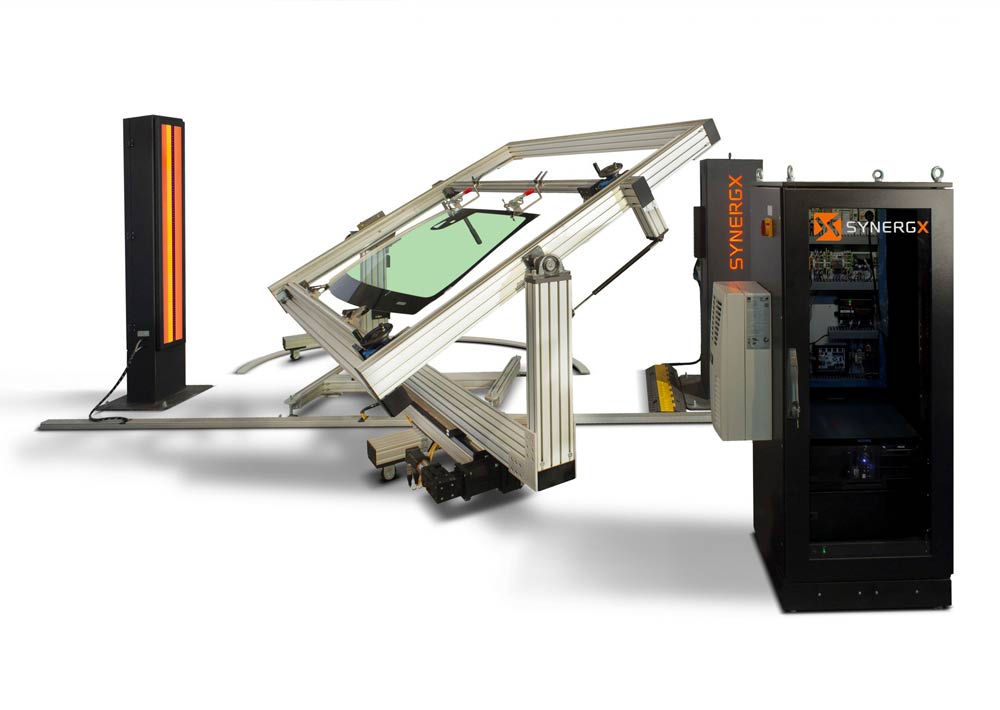

Curved Glass Inspection

CURVE 200

- Automotive windshields and backlites

- Proprietary Chroma™ optics to keep image sharpness over a very large depth of field

- Glass and paint Inspection with transmissive optics

- Vertical Conveying

Optical Characteristic Measurement

WINDX LAB

- Automotive windshields, backlites, laminated sidelites and sunroofs

- Approved by automotive OEMs

- Technology and innovation leader

- Custom flexible conveyor for advanced inspections

- Double image and camera zone inspections

Optical Characteristic Measurement

WINDX INLINE

- Automotive windshields, backlites, laminated sidelites and sunroofs

- Approved by automotive OEMs

- Technology and innovation leader

- Double image and camera zone inspections

Contact our glass experts to learn about the full comparaison between the systems

Send us a request for information and a specialist in your market will contact you.