Curved Glass Inspection

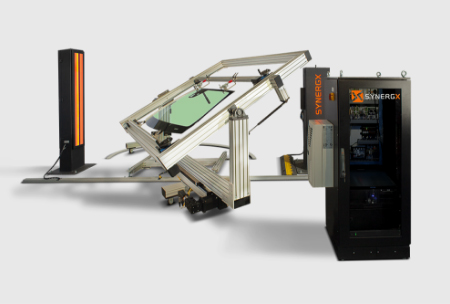

CURVE

The CURVE 60 and the CURVE 200 is a family of products providing high quality glass processors with an integrated inline bent glass surface and paint inspection solution meeting the high level required by the OEM Automotive or other bent glass manufacturers.

CURVE 60

The CURVE 60 system provides complete glass surface (transmission) inspection and paint (reflection) inspection on panels with up to 60 mm of bend deviation.

CURVE 200

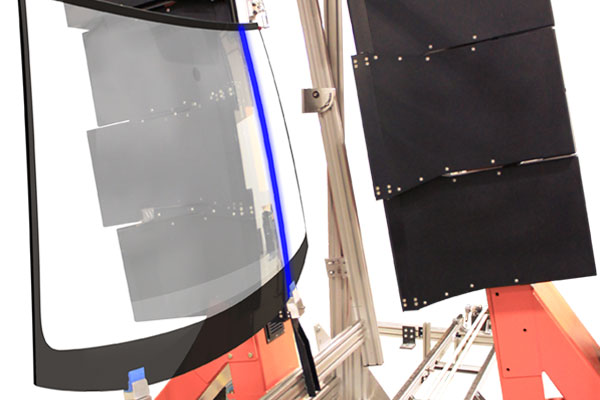

The CURVE 200 system is an innovative real- time optical inspection system for defect detection on windshields at the end of the lamination process.

CURVE 60 systems

Benefits

Improves product quality to meet glass manufacturer’s increasingly high expectations

Reduces production costs through productivity improvement

Captures key data for continuous process improvement

Convenient footprint and flexible interface allow easy integration into existing production or greenfield project

Features

Improve the quality of your products. Improve your manufacturing processes and productivity.

Glass Transparency

To clear glass inspection (6% to 92% transmittance)

Bent

Up to 60mm

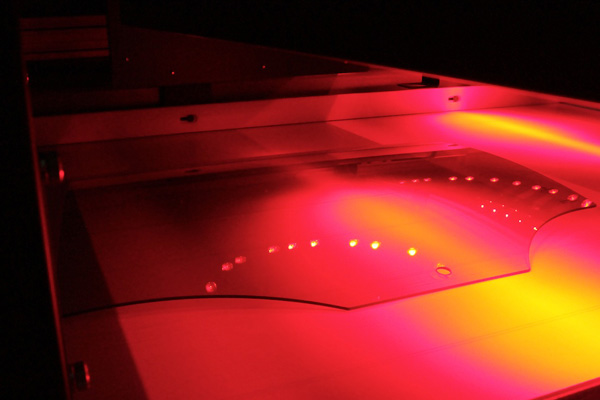

Scratch

Inspection on the opposite surface of the paint band with proprietary reflective lighting technology

Speed

Fully automated, non-contact inspection at line speeds up to 60 m/min

Cycle Time

CURVE 200 systems

Benefits

Inline defect detection on bent windshield products up to 200 mm in depth

Optional installation combined with the SYNERGX WINDX Inline optical distortion measurement system

ASTM 5 scratch detection capabilities

Cycle time of 6 seconds installed on a vertical conveyor configuration

Features

Improve the quality of your products. Improve your manufacturing processes and productivity.

Innovation

Patented optics provides true high quality imaging capabilities with 200 micron pixel sizes, or 100 micron pixels, on a deep field of view, with no mechanical moving parts

Feedback

High-accuracy and highly repeatable real-time process feedback

Inspection

100% inspection results to monitor production process quality and eliminate un-necessary product recalls

The CURVE 60 and CURVE 200 inspection systems are fully integrated to your manufacturing process and are based on the Synergx GI platform

FROM THE SYNERGX HUB

SynergX Curve inspection system family for bent glass.

The Curve family of glass inspection systems is part of the fully automated zero-defect glass inspection solutions designed specifically for bent glass.

Contact our glass experts to learn about the full comparison between the systems

Send us a request for information and a specialist in your market will contact you.

Other popular products in the glass industry

Welcome to a new era of precision.

Case Study

AGNORA detects architectural glass defects faster thanks to SYNERGX

Discover how SYNERGX contributes to fulfilling AGNORA’s mission to produce impeccable architectural glass!