Geometric Dimensioning and Tolerancing (GD&T)

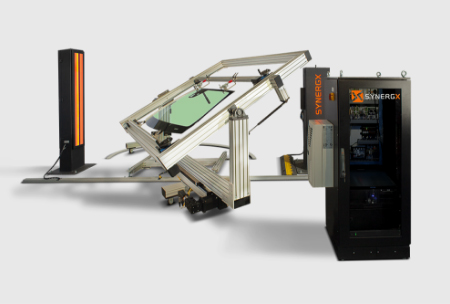

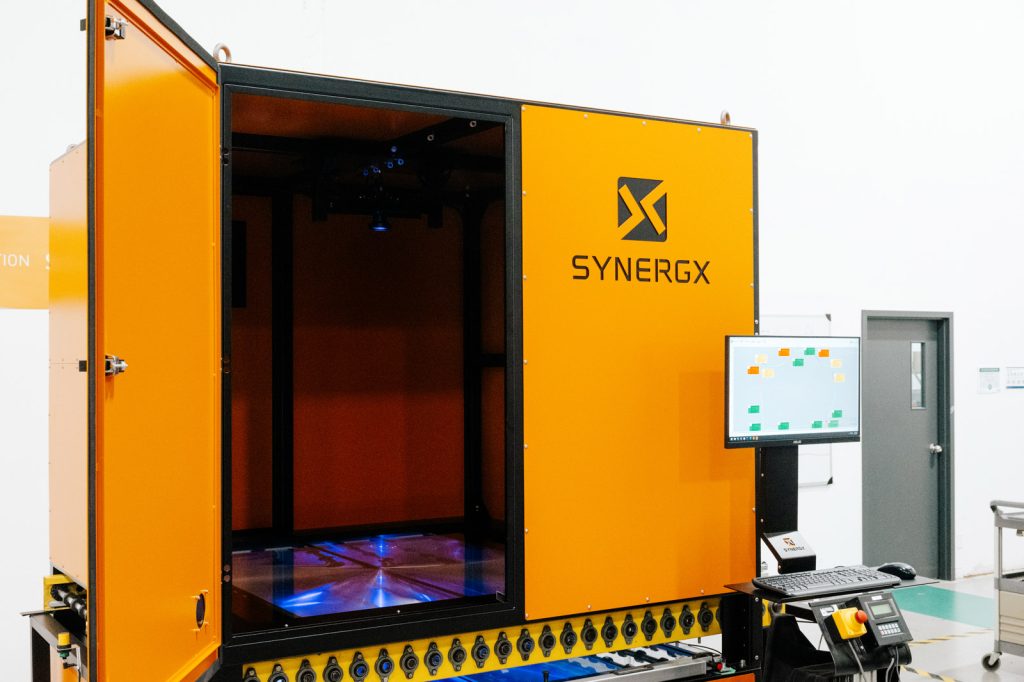

DIMX

The DIMX is a fully automated inline dimensional measurement metrology system for flat glass panels specifically designed to optimize the yield of high-volume glass manufacturing lines. It guarantees a high level of quality and provides real-time feedback to manufacturing processes.

Benefits

Improve product quality to meet glass manufacturers’ increasingly high expectations

Convenient footprint and flexible interface allow for easy integration into existing production lines or greenfield projects

Reduce production costs through productivity improvement

Can be integrated to production lines with SURFX or EDGE line of products that are already installed

Capture key data for continuous process improvement

Improves the quality of your products. Improves your manufacturing processes and productivity.

Features

Measures

Hole size, Hole position, Hole roundness, Hole-to-hole distance, Hole-to-edge distance, panel size

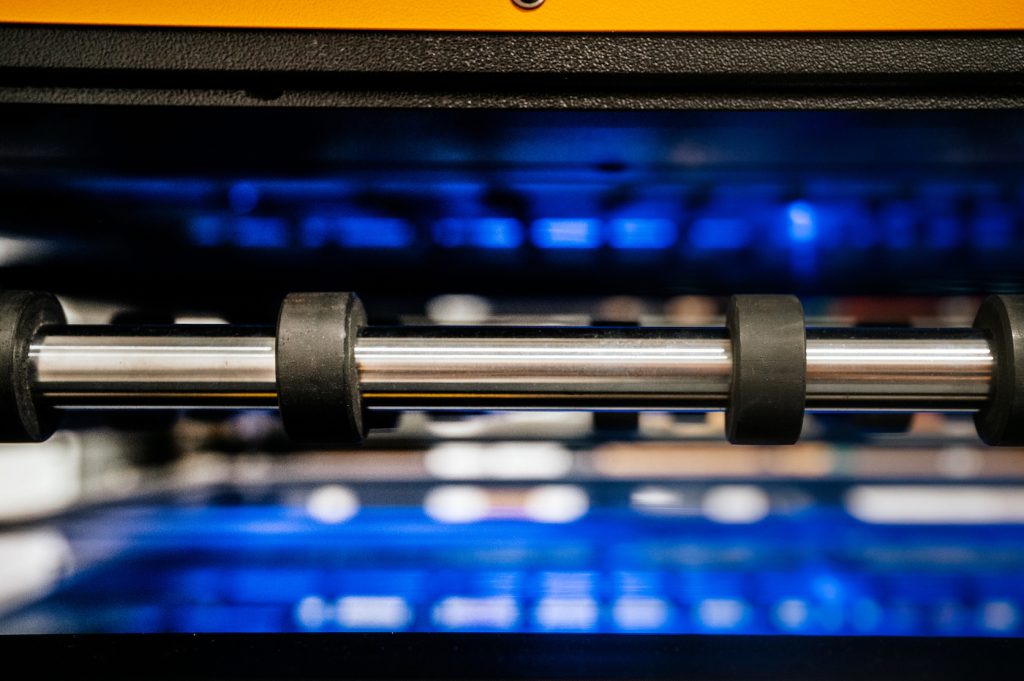

Speed

Up to 60 m/min

Cycle Time

Industry-leading cycle time of 4.5 seconds

Repeatability

High inspection repeatability & accuracy for glass thickness between 0.75mm and 20mm

Options

- Advanced PLC interface

- IDT workstation – Remote operator inspection display terminal

- IoTX - Industry 4.0 real-time access to inspection result data

- Offline workstation – Offline replay of saved scans and model configurations

The DIMX measuring system is fully integrated to your manufacturing process

“Our new DIMX system brings glass geometric dimensioning and tolerancing (GD&T) to a whole new level of accuracy, repeatability, and automation.”

Normand McGuire, Product Manager at SYNERGX

Designed for glass manufacturers that have a wide range of glass types, high volume and fast production cycles, and are looking to implement a high precision glass measuring system.

Call our glass experts to learn about the full comparison between the systems

Send us a request for information and a specialist in your market will contact you.

Other popular products in the glass industry

Welcome to a new era of precision.