Demand has remained highly robust in the glass manufacturing industry, thanks to explosive growth in various market segments, such as the automotive, appliance and architectural sectors, where competition is rampant.

Several trends are propelling the glass industry in 2022 and beyond, including:

- Unabated demand for higher quality and high-performance glass across all markets

- Glass as a structural element and a key component in building designs

- Requirements for bigger and more complicated glass products (larger lites and more decorative glass), which especially rings true for architects

- More sophisticated features for glass used in appliance applications

- Hyper-personalization of glass products as a competitive differentiation

- Smart glass and improved glass styling for vehicles in the automotive industry

While market conditions are exceptionally favourable, glass manufacturers face unprecedented challenges impacting different areas of their businesses. A shortage of skilled workers, snarled supply chains, and skyrocketing material costs—all compounded by the global pandemic—prevent glass manufacturers from expanding production capacity and accelerating actual throughput.

Different types of legislation are also exacerbating glass manufacturers’ headaches. From pressure to reduce energy consumption to better managing chemicals to finding more sustainable ways to produce glass, glass manufacturers must grapple with ever-stricter environmental legislation. Other legislation, like that proposed by lobbyists who want to reduce the billions of bird deaths yearly caused by glass facades, is simply adding a thorn in glass manufacturers’ sides.

As a result, glass manufacturers are turning to new technologies and automation to mitigate the ripple effects of the challenges above. Investing in robotics, for example, means glass manufacturers can run 24/7 with a limited staff to tackle high-volume orders and shrinking lead times.

Many also leverage to maintain consistent and reliable product quality, despite a lack of experienced metrologists and glass inspectors. These new solutions can help detect anomalies and defects faster, minimizing consumable waste and improving customer satisfaction.

Finding the right partner can be difficult as glass trends and production technologies evolve rapidly. Here are our top 3 tips for choosing the right equipment partner for your glass manufacturing business.

- Significant investments in R&D

The best technology partner for glass manufacturers must be on the leading edge of innovation, with a proven commitment to research and development. Relying on legacy solutions, which can be rife with problems for a glass manufacturer to deliver the products its clientele has come to expect, can compromise agreements and customer loyalty.

A partner constantly developing new solutions based on future-proofed technologies can support glass manufacturers as they modernize their production workflows for the highest effects and optimized costs.

- Expertise in your unique sector

Cookie-cutter approaches in glass manufacturing don’t cut it. Depending on the market segment a glass manufacturer caters to, the intricacies of customer needs, quality and performance levels, and other production considerations can differ greatly.

Look for a glass equipment partner with a track record of assisting other manufacturers in your sector. You’ll benefit from niched know-how that truly addresses the product, operational and customer hurdles you undergo on a daily basis.

- Comprehensive support footprint and services

Nothing busts a bottom line worse than having to troubleshoot equipment and shut down a line—with little support from a vendor. Support in a different time zone or bogged down because of language barriers is frustrating at best and profit-gouging at its worse.

Apart from contractual support agreements, determine how easy it is to get support from your equipment manufacturer. If the supplier says all the right things, what are the proof points? Concretely, what does fast support mean? Does the company have adequate tiered support, which enables case escalation with experts—but without being bounced from one to another? Does the vendor have multiple locations around the world that provide localized support? Digging deep into what a potential partner defines as support is critical, especially in the fast-paced world of glass manufacturing.

It is undoubtedly a new frontier for glass manufacturers, and navigating through each market and HR challenge requires creative solutions to boost resilience. Integrating ahead-of-the-curve technologies should play a role in a glass manufacturer’s long-term strategies. But it starts with the right partner. Extensive vendor research should not be underestimated for any business looking to remain profitable and prosperous for years to come.

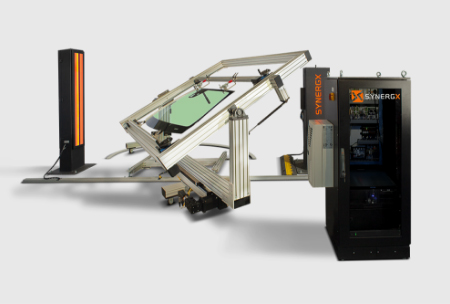

About Synergx

World-leading provider of non-contact inspection & metrology solutions designed to optimize glass manufacturing processes.

We make you see things.