For nearly 2000 years, glass has been used to build many stunning architectural projects. Despite its long-standing history in construction, today’s glass continues to undergo innovations that are pushing the limits of the technology used and performance levels. For example, new architectural glass manufacturing techniques can prevent heat transfer, which hikes up cooling expenses in the summer.

In a nutshell, glass is made by mixing very pure sand or quartz with soda ash, dolomite and limestone and heating the mix at a very high temperature until it melts and turns into a liquid. During this heating process, the sand undergoes a complete chemical transformation to become the transparent amorphous solid material known as glass. Adding dyes to the basic mix allows to produce coloured glass. There are other basic ingredients that can produce glass. Borosilicate is more popular now as they are ubiquitous in electronic displays and devices.

Advantages of Glass in Architecture

Glass is, indeed, probably the best-known construction material that perfectly blends aesthetics and function. Used extensively in both residential and commercial buildings, glass offers a wide range of advantages for building designers. Let’s look at them in more details.

Aesthetics

Glass’ clean and sleek lines offer a contemporary and impressive aesthetic. Glass transmits, refract and absorb light, which in turn elevates the beauty of a building’s outdoor design as well as indoor ambience. In addition, glass provides natural and relaxing lighting—all while making interiors look more spacious. Glass has also been well documented to improve building occupants’ moods and productivity levels.

Maintenance

Thanks to their smooth and glossy surface, most types of glass can be cleaned very easily. Some glasses are even self-cleaning (hydrophobic and hydrophilic), meaning that the surfaces keep themselves free of grime and dirt.

Durability and Performance

As a dimensionally stable building material, it is highly resistant to corrosion, extreme weather conditions, breaches and other sources of potential damage. The physical properties of glass make it very resistant to abrasion, high temperatures, rust and vermin. Glass is also a fantastic sound insulator. Furthermore, glass does not experience any yellowing, weathering or clouding as it can transmit 80% or more of daylight. As a material, glass maintains its structural integrity and appearance for a very long time. Finally, glass is the only cladding material that allows energy to be harvested in a building, either as light or heat.

Versatility

Glass can be cut and manufactured into almost any shape or form, which enables architects to create stunning glass buildings or interiors without compromising on design. Glass can be used for a myriad of applications, such as unique fenestration, facades, doors, partitions, storefronts, floors, roofs, elevators, balconies, ceilings, skylights, design elements and more.

Sustainability

Glass is the only material that actually offers energy gains. It enables building designers to apply both active and passive daylighting techniques, helping to reduce artificial lighting requirements. Energy efficient glass, including low-emissivity glass (low-e) can contribute to lowering energy

consumption and earning LEED points. Finally, glass is infinitely recyclable, which lowers greenhouse gas emissions and avoids the extraction of new raw materials.

Cost Considerations

Architectural glass products can be very cost-effective cladding and design materials that can boost energy savings and lower utility bills. It is an excellent material for thermal insulation and waterproofing as well. Due to the sheer range of glass products on the market, features and performance levels, many architects turn to glass as the perfect building material to keep their budgets in check.

Types of Architectural Glass

The aesthetical and technical properties of architectural glass allow an almost limitless array of applications for both indoor and outdoor applications. Here are some of the most popular architectural glass products.

Basic Architectural Glass Products

The most common architectural glass products are categorized as clear, extra-clear and coloured.

Clear glass is produced in a float line without additives to be completely transparent. However, the iron contained in the raw materials causes a slightly green tint. Extra-clear glass, also known as low-iron glass, contains very little iron to eliminate the greenish tint found in clear glass.

Coloured glass, as the name implies, is a type of glass that is coloured. They are made by adding mineral or purified metal salts to the raw materials. Coloured glass was popular from the 1950 to the 1980 because they allowed to lower the solar heat gain. But they have lost the architects’ favour when transparent coatings were developed.

Safety Glass

Safety glass is glass with additional features that make it harmless to people and the surrounding environment if it is struck, breaks or falls to the ground. Safety glass is renowned for its strength and even fire resistance.

There are two types of safety glass: laminated glass and tempered glass. Laminated glass is manufactured by binding two or more panes of glass with a layer of plastic. If the laminated glass does break, the fragments will adhere to the middle layer rather than fall to the ground. Laminated glass is ideal for architectural products that require screening UV rays, soundproofing, and buildings subject to high risks, such as banks, museums, and storefronts, or subject to extreme weather conditions, like hurricanes and high winds.

Tempered glass is a safety glass that is produced by using heat to strengthen the glass. If tempered glass breaks, it shatters into tiny round pieces rather than sharp shards. Tempered glass is typically used for interior applications: partitions, offices, conference rooms, decorative panels, doors and windows, etc.

Coated Architectural Glass Products

Coated glass is a broad term for any architectural glass product that features a metallic coating or paint. It can be transparent, translucent or opaque.

In Louis XIV time, mirror was the most coveted luxury item. That led to the creation of the Manufacture Royale des Glaces à Mirror in Saint-Gobain, north of Paris in 1665. Now, mirror is a commodity product found in all homes. So are transparent metallic coatings that provide solar control and insulation.

While used as early as in ancient Egypt and Mesopotamia to decorate glasses and vases, fritted glass has experienced a renaissance in modern architecture with the advent of ink jet printing. Frit is a ceramic paint similar to the one used in pottery that can be laid out into patterns, like lines or dots, or full-colour pictures. Frit glass techniques are often used to control views of a highly transparent building, make a graphical statement, or blur away glass joints. Painted and printed glass can feature imagery, patterns, texts or simply colours to create unique and spectacular environments. Paint and printed glass are even being used for outdoor building fenestration to save the estimated millions of birds killed each year when they fly into glass.

Insulated Glass

Typically offered in dual and triple glazing, insulating glass unit features two or three lites of glass separated by dry air or an inert gas like argon. This gap prevents heat loss through doors and windows. Again, as the name suggests, dual-pane glass insulates twice as much as single-pane glass. Triple-pane glass offers even better energy efficiency.

Architectural glass for commercial and residential buildings offers several advantages: beauty, design flexibility, safety, energy efficiency, durability, electric, sound and thermal insulation, ease of maintenance…the list goes on and on. There are very few other construction materials on the market that have as many compelling features and last for ages. We are confident that with the latest technological advances in glass production, the popularity of architectural glass is here to stay!

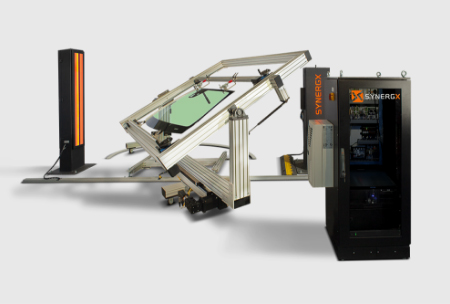

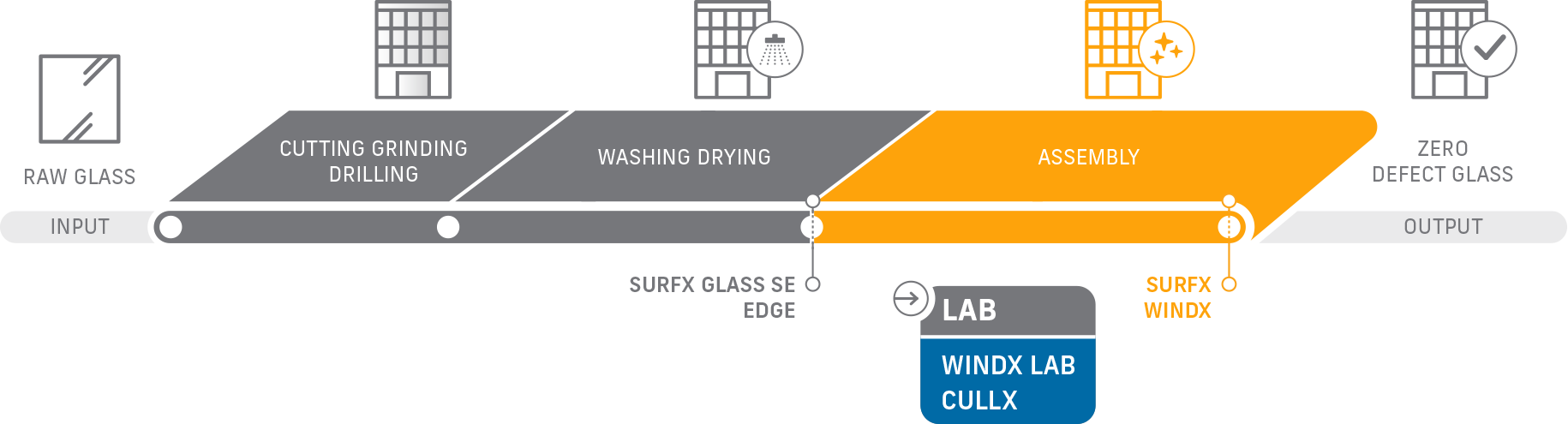

About Synergx

World-leading provider of non-contact inspection & metrology solutions designed to optimize glass manufacturing processes.

Synergx offers a complete and integrated platform for architectural glass inspections.