The English version of the text is provided below.

SYNERGX will establish a ‘demo center’ in Turkey

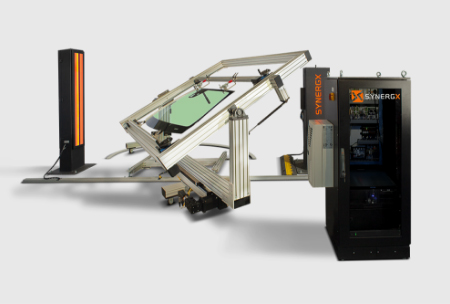

Stating that SYNERGX, the leader of non-contact inspection and metrology solutions for the glass industry, has a serious motivation to establish a ‘demo center’ in Turkey, Turkey Country Director Volkan Türemiş said, “We currently offer solutions to the glass industry with 8 different product families. “We are constantly improving with technology,” he said.

ALI ŞAHİN/BURSA

SYNERGX, which is based in Canada and carries out its activities in many parts of the world, has accelerated its marketing activities in Turkey. Reminding that they are the world leader in non-contact inspection and metrology solutions designed to optimize glass production processes, SYNERGX Turkey Country Director Volkan Türemiş said, “If I explain what we do in simple terms, we are a global company that targets the glass industry and provides the installation of in-line quality-control systems in production in this sector. . In this period when we are talking about automation, robotic technologies and industry 4.0, the margin of error that will occur when quality control processes are left to humans needs to be minimized. “We make a significant contribution to the efficiency of the processes by minimizing the margin of error, especially in glass production, which has a 0.5 percent wastage share during each move and involves significant costs in each process,” he said.

Reminding that Turkey is Europe’s largest and one of the world’s 5th largest producers in glass production, according to the “Glass Sector Report” data published by the Ministry of Industry and Technology in 2020, Türemiş said, “Glass is a product where very high volume production is made and everyone’s quality expectations are met.” It is a sector where it is different. We should not think that production in Turkey is limited to glass used only in homes. In our country, glass with various features and strengths is produced for many sectors, especially automotive and white goods. Some of these glasses produced go through several processes, and at the end of each process, those with reference values that will be considered incorrect must be separated. Applying the second stage to a faulty product in the first stage brings a serious cost since high volume production is made. As SYNERGX, we focused on these processes with the quality control systems we developed for each process. We prevent products outside the reference value from entering the next process by making the necessary checks within the line via cameras. For example, we do not send glass that has a defect in the preliminary stage to the painting stage. “In addition, for example, we digitalized the measurement methods used in tempered glass standards and made the measurement and storage facilities required for certification much easier.”

“We solve problems remotely”

Stating that SYNERGX understands the industry and offers innovative solutions in line with the needs, Volkan Türemiş said, “There is no margin for error in industrial glasses. In order to produce in accordance with certifications, it is necessary to use developing camera and artificial intelligence technologies and algorithms. We all know that automation in this field works with much less margin of error than humans. When the data obtained in these processes are used correctly, R&D projects can be developed that will provide serious savings in important items such as energy. As smart camera systems developed, they began to provide a lot of data. We also adapt to these innovations. We install systems with high initial purchase costs, but we actually offer solutions to many of the needs of companies. The systems we have established are very consistent and we can solve 95 percent of possible problems with a remote connection. “Since this is an in-line system, it provides a significant advantage in terms of continuing production without stopping,” he said.

Stating that he has been carrying out SYNERGX’s marketing activities in Turkey for about a year and a half, Türemiş said, “We are trying to transfer SYNERGX’s technologies to our country in the right language. We want to establish a demo center in Turkey. We expect steps in this regard to be taken following the decision to be taken in 2024. There is a serious motivation in this direction at the company headquarters. We currently offer solutions to the industry with 8 different product families. “We are constantly improving with technology,” he said.

>>>>>>>>>>>>>>>>>>