Laminated vs tempered glass. What’s the difference?

If you are an architect, building designer or even a construction contractor, you may be wondering which of these two is the best safety glass for your upcoming project.

Let’s look at the advantages and disadvantages of laminated vs. tempered glass in more detail so that you can make the right choice in safety glass.

What is safety glass ?

Above all, it is important to understand that laminated and tempered glass are part of the safety glass category. Safety glass is a type of glass that is produced to reduce the risk of injury; both laminated and tempered glass, are less prone to causing injury to people and the surrounding environment.

What is laminated glass and how is laminated glass made?

Laminated glass was invented in 1903 by a French chemist named Édouard Bénédictus following a laboratory accident. Its first industrial use was in the automotive industry to produce windshields. iN the 1970 it made its way into architectural applications.

Laminated glass is manufactured by binding two or more layers of annealed or heat-treated glass with a tear-resistant layer of plastic. There are now three types of plastics used: polyvinyl butyral (PVB), ethylene vinyl acetate (EVA) and ionoplast produced under the SentryGlas® brand. The typical thickness range of these membranes is 0.015 in to 0.090 in (0.4 mm – 2.3 mm).

This multilayered assembly increases the strength so it can withstand the impact of flying fragments and debris caused by an object or a person, such as a bullet or thief, that strikes it. In case of breakage, the glass fragments adhere to the plastic, rather than falling to the ground. Laminated glass is constructed to prevent it from shattering as it holds in place within the frame.

What are the benefits of laminated glass ?

There are several benefits to using laminated glass. Here are the top features:

- Robust strength and anti-shock performance thanks to its multi-layer composition

- Laminated glass cuts 99% of harmful UV light

- It betters the sound attenuation/soundproofing.

- Larger sheets of laminated glass can be cut without compromising performance.

- Laminated glass is ideal for environments that are subject to extreme weather conditions and high wind loads, like hurricanes.

- It is the only way to produce in bullet-resistant or high intrusion resistant assembly.

- Finally, because there is no high temperature process, it remains perfectly flat, and it does not show any anisotropy.

Typical applications of laminated glass

Laminated glass is renowned for its use in high-security and high-risk applications to protect valuable assets from breaches, such as banks, jewelry shops, museums, etc. Other common uses of laminated glass include schools, hospitals, all overhanging applications like skylights, glass floors, railings and facades, partitions and showcases in stores, high-end patio doors, and other decorative building or artistic applications.

What is tempered glass and how is it made?

Tempered glass is also a safety glass and is called toughened glass in Europe. It has a different production method. It is manufactured by heating and rapidly cooling it (quenching). This causes compressive stresses on the surface of the glass and tensile stress in the body of the glass.

Tempered glass is 4 times stronger than annealed glass. If it breaks, tempered glass shatters into small pieces as opposed to large shards, which reduces the possibility of harming people and animals as well as damaging the surrounding environment.

What are the benefits of tempered glass?

- Tempered glass has a high tensile strength, it will support high stress around holes and notches. It can bend further without breaking.

- This increased its resistance to impacts and forces like a rock being thrown at it, etc.

- It is known for its high thermal resistance so it can withstand drastic temperature changes

- This type of safety glass offers a lot of design flexibility, including etching and colouring.

Nevertheless, keep in mind that tempered glass cannot be cut once it has undergone its thermal or chemical treatment.

Typical applications of tempered glass

Tempered glass is often used for interior safety applications, window and door systems, conference rooms, restaurants and hotels, and residential homes. Tempered glass is also suitable for commercial buildings and skyscrapers that require large windows and protection from outside elements.

How to choose between laminated and tempered glass?

There are several factors to consider when choosing the right type of safety glass for your project. Laminated and tempered glass is available in different thicknesses, tints and colours. However, there are some inherent differences. For example, due to the cost of the interlayer and the complexity of equipment required for its manufacturing process, laminated glass tends to be more expensive. If price is your number-one concern, tempered glass may be your best option.

As mentioned before, tempered glass cannot be cut once it has undergone the tempering process. Therefore, all your design and features, including holes, size, and shape, must be decided before you send in your order. If adjustments are needed, the glass will have to be remade, which will inevitably entail more costs.

The best way to determine if you should opt for laminated or tempered glass is to ask yourself the following questions:

- Do you have significant budget constraints?

- Does your project require advanced safety/security and UV protection?

- Are there holes or notches?

- Will the glass be used for structural support or simply an element of design?

As with any architectural project, the final choice of materials, such as tempered vs laminated glass, depends on the applications, critical specifications, outdoor/indoor conditions, costs and timelines. Talk to your local glass expert today to learn more about which safety glass is right for you.

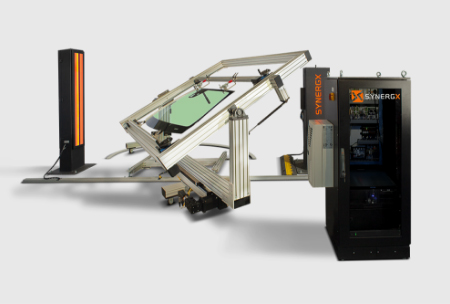

About Synergx

World-leading provider of non-contact inspection & metrology solutions designed to optimize glass manufacturing processes.

Did you know?

Did you know that Synergx offers a complete and integrated platform for architectural glass inspections?

Learn more about our solutions to elevate the quality of safety glass for architectural applications.