Product News

What’s New in WINDX 5.4?

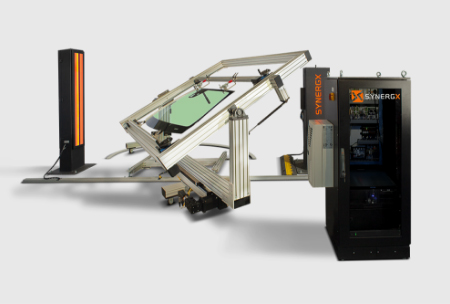

WINDX is a multi-feature, fully automated, non-contact metrology system designed for the characterization of optical properties of automotive glazing. In everyday words, it measures the distortion of what is perceived by the driver’s eyes when looking outside through the windshield, side glasses or backlite of the vehicle.

Glass inspection standards are becoming increasingly high and complex, requiring more and more cutting-edge glass inspection systems. The advancements of driving assistance technologies (ADAS), such as inboard cameras, contribute to the rise of the quality requirements in the automotive glass. These cameras, typically installed in the top center of the windshield, look through what is known as the camera zone. The camera zone must have minimal distortion for the camera to have a precise view of what is ahead of the moving vehicle so the vehicle can react appropriately to the outside world conditions.

The WINDX 5 system, released in 2022, introduced new features to take glazing inspection to a whole new level:

- Reliable measurement of optical characteristics to the paint borders

- Doubled resolution for improved assessments required by ADAS camera applications

- New orthographic projection for resolution uniformity and visibility on the entire glass surface

- Increase of the maximum glass size supported

- Installation uniformity and better reproducibility between sites

WINDX 5.4 pushes those limits yet further with:

- Up to 7 horizontal and 7 vertical filters

- Percentile statistics of distortion with acceptance criterion per zone

- Grouping of smart camera zones to account for glass positioning variations due to conveyor imprecision

- Filtering of thin heating wires in the camera zone

- Performance improvements for faster cycle time

These new features make the WINDX system more versatile and capable of providing the measurements and characteristics you need for your specific application and requirements.

As previously offered, the WINDX system is available as an inline solution for quality control on the production floor or as a lab system for new development initiatives.

About SYNERGX

World-leading provider of non-contact inspection & metrology solutions designed to optimize glass manufacturing processes.

Learn more about our automotive glass inspection solutions

Learn more about our architectural glass inspection solutions