The era of manually counting fragments of broken tempered glass is now over. Thanks to SYNERGX’s CULLX system you no longer need to complete this tedious task on your own.

The CULLX system automatically inspects and counts the fragmentation of broken tempered glass to overcome the lack of reproducibility, manual locating of fragments and counting areas. This system can be used to ensure conformity of tempered glass to ECE R43 and ANSI/SAE 261.1 for automotive glass standards, and EN 12150-1 and ANSI Z97.1 for architectural glass standards. The CULLX system is designed to be installed as part of quality assurance in the last stages of the production process.

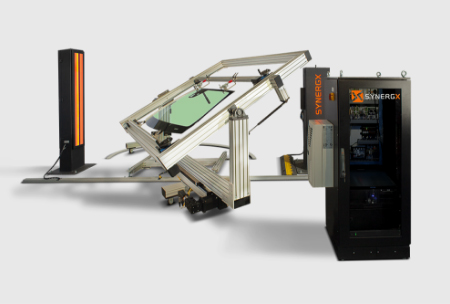

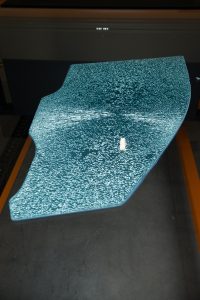

Glass inspected by the CULLX system may be of any size, shape and bend (up to 300 mm), with light transmissivity from 5.6% to 92%, with or without paint. The system will inspect the clear glass area, considering and ignoring heat/antenna lines and logo areas in the calculation.

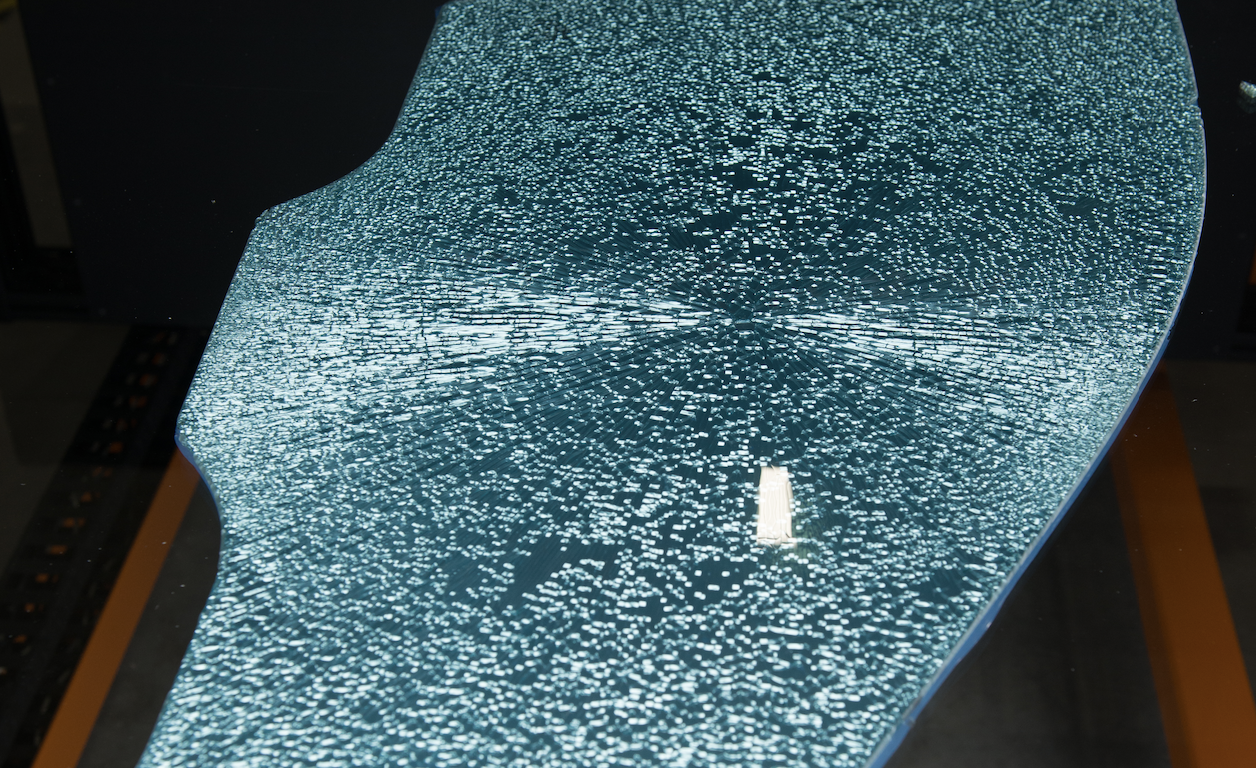

Prior to inspection, surface 1 (the outside) of the glass must be covered with an optical-grade plastic film specifically engineered by SYNERGX to ensure the integrity of the glass when it is broken. The system supports glass up to 1250 mm x 1800 mm in size and 10 mm in thickness. The glass can be placed on the inspection table in any orientation.

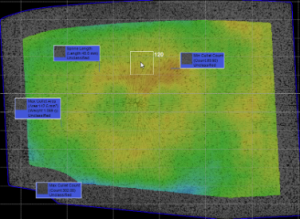

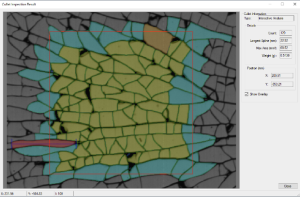

The CULLX comes as an offline lab system that can be used anytime during a production run. Inspection result data can be saved offline for archiving purposes. The result data includes an image of the broken glass with annotations for the longest spline, the largest fragment and weight, as well as the squares with minimum and maximum fragment counts. Tolerance values can be set for each of these inspection results with pass, warning or fail. Configurable parameters include the square size, glass thickness, glass density, the width of a no-inspection perimeter around the glass. You can also configure the activation of a proprietary paint avoidance feature to detect and ignore heat/antenna lines and logos in the fragmentation calculations.

The user interface shows a heatmap of the density of the fragmentation. Color-coded result labels indicate the four main results.

About Synergx

World-leading provider of non-contact inspection & metrology solutions designed to optimize glass manufacturing processes.

Did you know that SYNERGX offers a complete and integrated platform for glass inspections?

Learn more about our automotive glass inspection solutions

Learn more about our architectural glass inspection solutions