SYNERGX Technologies introduced the AURA system in early 2010; now deployed in over 20 manufacturing plants, the AURA is an optical distortion measurement system designed for automotive glass products. It can be installed both on the production line after the tempering furnace, or in a lab setting for research purposes. Three years after its original release, SYNERGX has announced a major enhancement to its user interface: AURA 2.0.

ABOUT AURA 2.0

The all-new AURA 2.0 system builds upon past successes with a redesigned, more precise user experience that runs faster and that is easier to use. The graphical user interface (GUI) has been revamped to a streamlined menu system and improved drawing tools to annotate the saved product model. The recent history browser offers review access to the latest scans. Newly added is the IDT capability; analysis of the different scans can be accessed at a remote location away from the production line. In addition, independent view options can be set for both screens at the display terminal.

The database now includes a complete image results field, which displays saved images in a compressed format, allowing much larger images than the original version. It also has an integrated, automatic cleanup to better manage saved files and system function without overwhelming customer networks. The user manual has also been simplified to improve the on–site training process.

about synergx

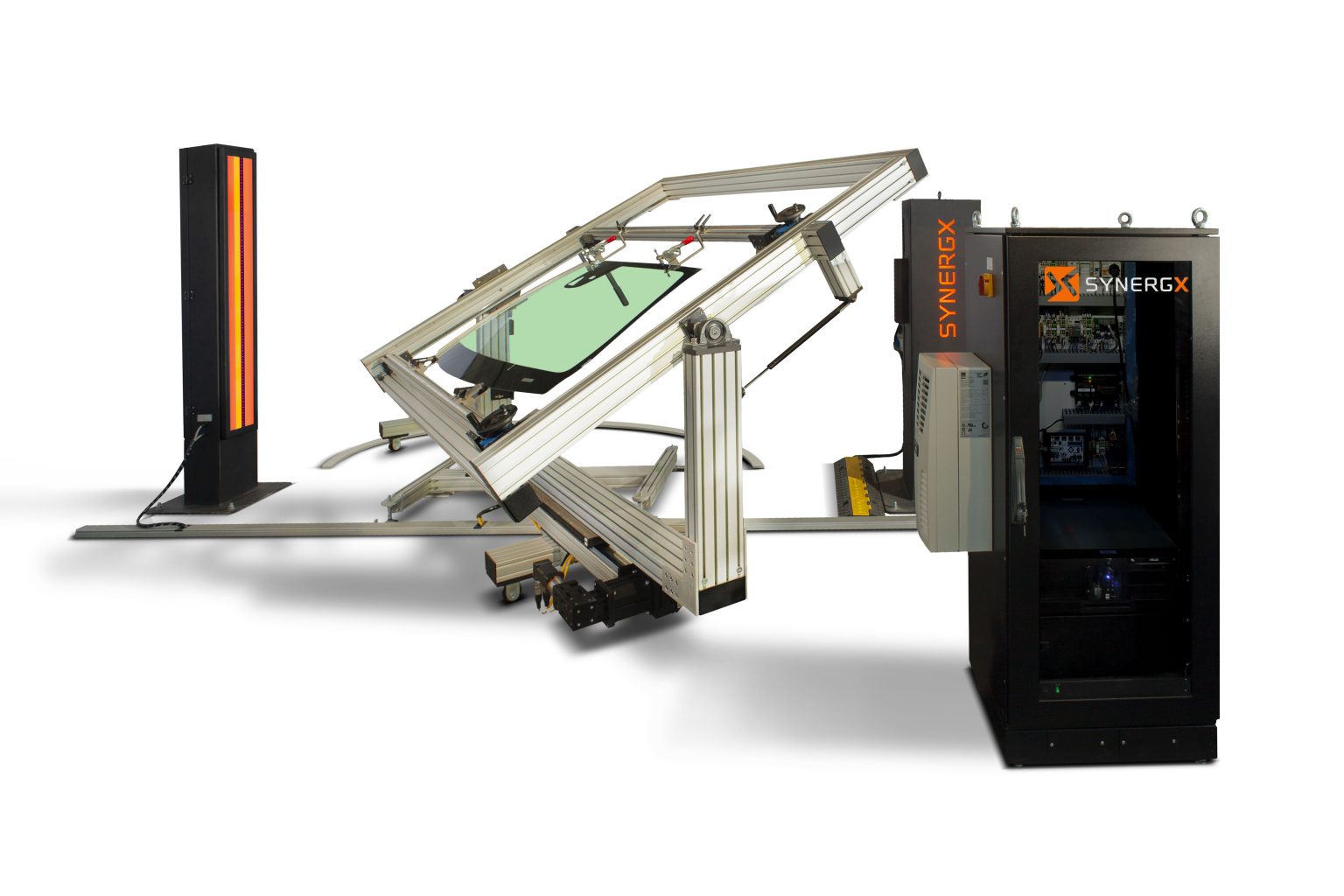

SYNERGX Technologies designs turnkey glass inspection systems for industrial glass manufacturers around the world, specialized for automotive, photovoltaic, appliance, bottling and architectural glass. The company pushes the boundaries of cold-end glass processing, from enhancing the surface and grinded edge inspection of cut glass to the introduction of a completely automated, inline & non-contact metrology solution.