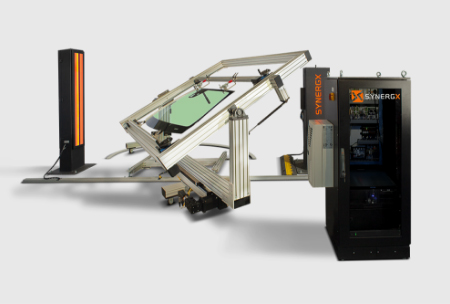

Glass dimensions are an important aspect in manufacturing automotive glass parts. Improper size of glass can disrupt the production process and create reasons of failure during final assembly at a car manufacturing facility. As a solution to this issue, SYNERGX launched its new DIMX product for a complete in process dimensional measurement of flat automotive glass.

DIMX is the first in-line metrology system with 100% QC (Quality Control) on all critical dimensions. This revolutionary inspection system is a complete glass flat panel GD&T solution (Geometric Dimensioning and Tolerancing) at 0.1 mm accuracy with an operator-friendly interface, a one-click SKU changeover and a full database result archiving.

With DIMX, glass manufacturers eliminate costly mechanical gauges currently used in a statistical sampled QC analysis and key real-time process information on cutting, drilling and grinding equipment is provided. Combined with the production management software modules developed by SYNERGX (PMware), DIMX significantly improves glass processing yields.

“We are thrilled to be the first company to provide the automotive glass industry with such a high performance metrology tool” says Stéphane Lemieux, CEO at SYNERGX. “In combination with our existing defect inspection systems, we provide solutions at a number of stages in the manufacturing process with the benefits of improved quality, increased productivity and process efficiency – ultimately resulting in a competitive advantage for our customers”.

With hundreds of systems installed in over 20 countries worldwide, SYNERGX Technologies Inc. is a leading global supplier of automated optical inspection technologies for the glass industry including photovoltaic, automotive, appliance and architectural glass. SYNERGX Head office is located in Canada and customer support services are available in China, Europe, South Korea, South Africa, Japan and South America. For further information, you can visit our website at www.synergx.com.