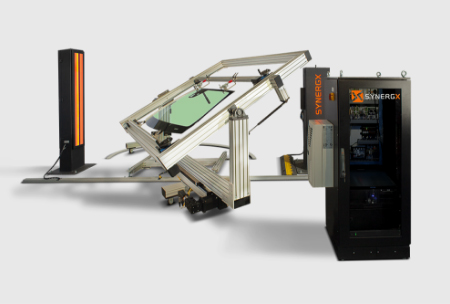

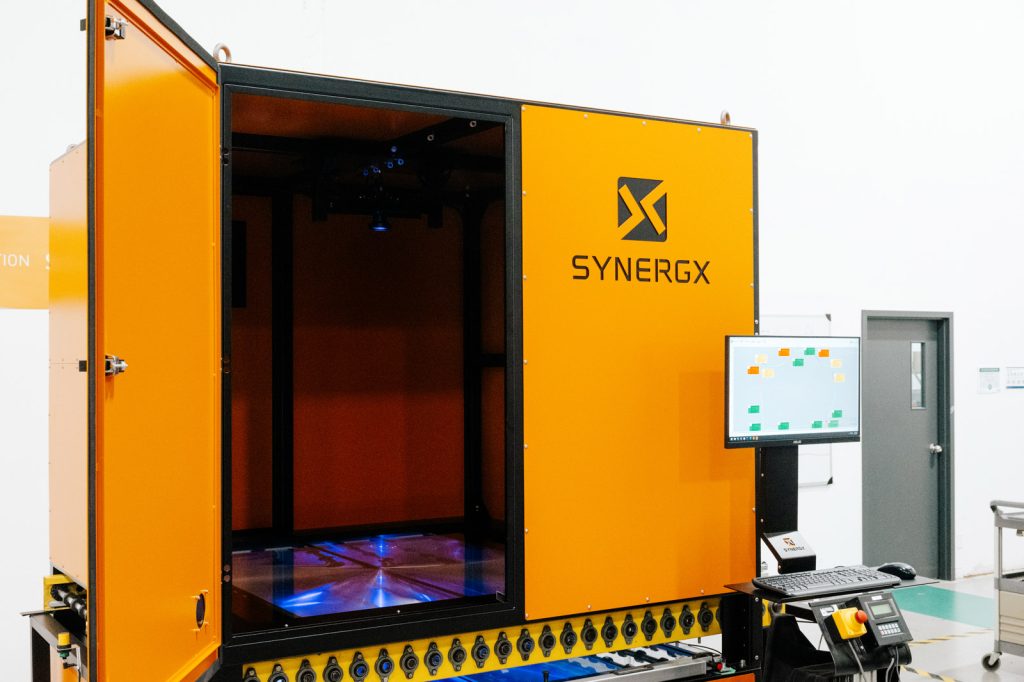

Measuring flat glass panels has never been easier. The new DIMX system from SYNERGX brings glass geometric dimensioning and tolerancing (GD&T) to a whole new level of accuracy, repeatability, and automation.

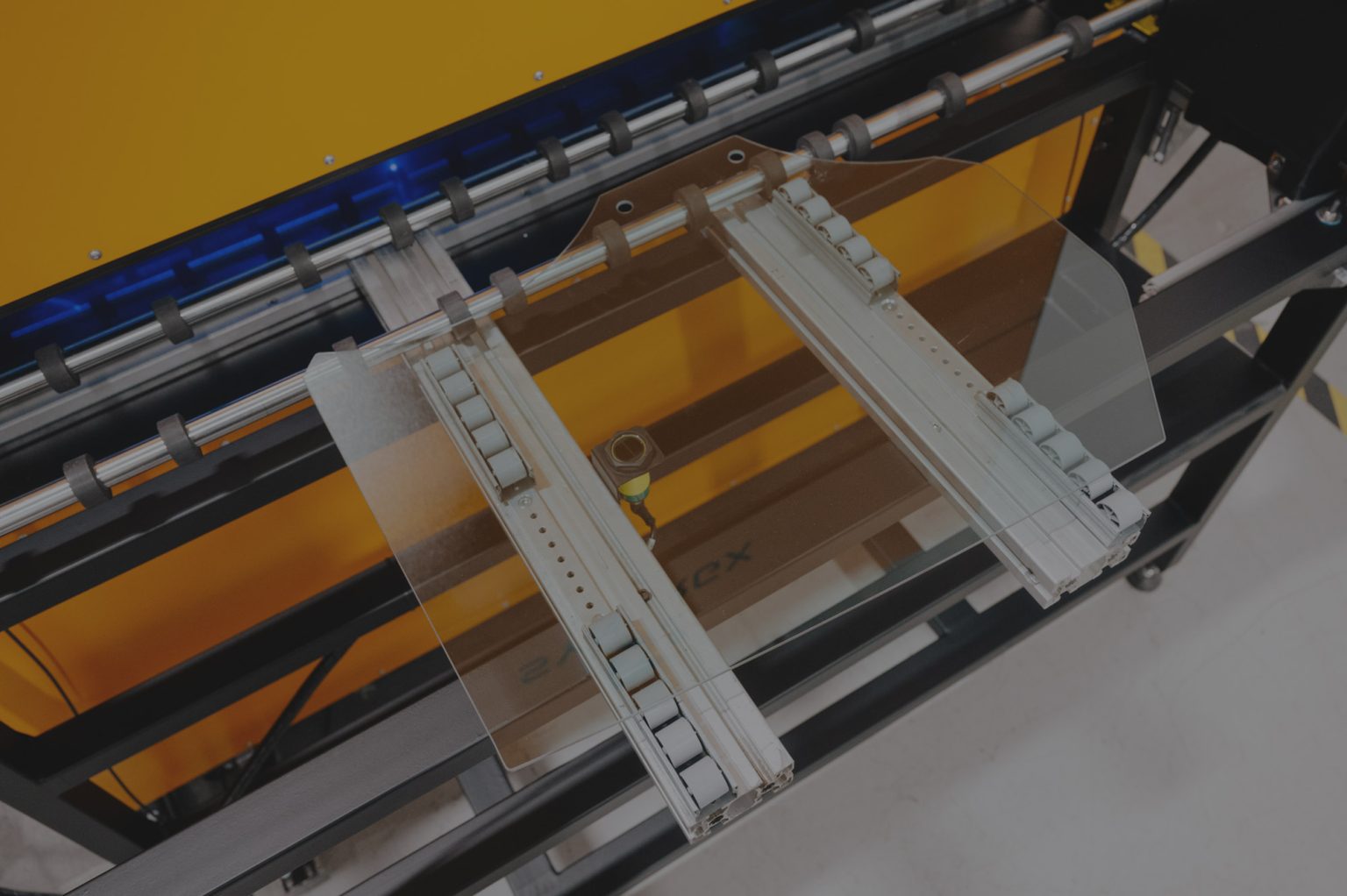

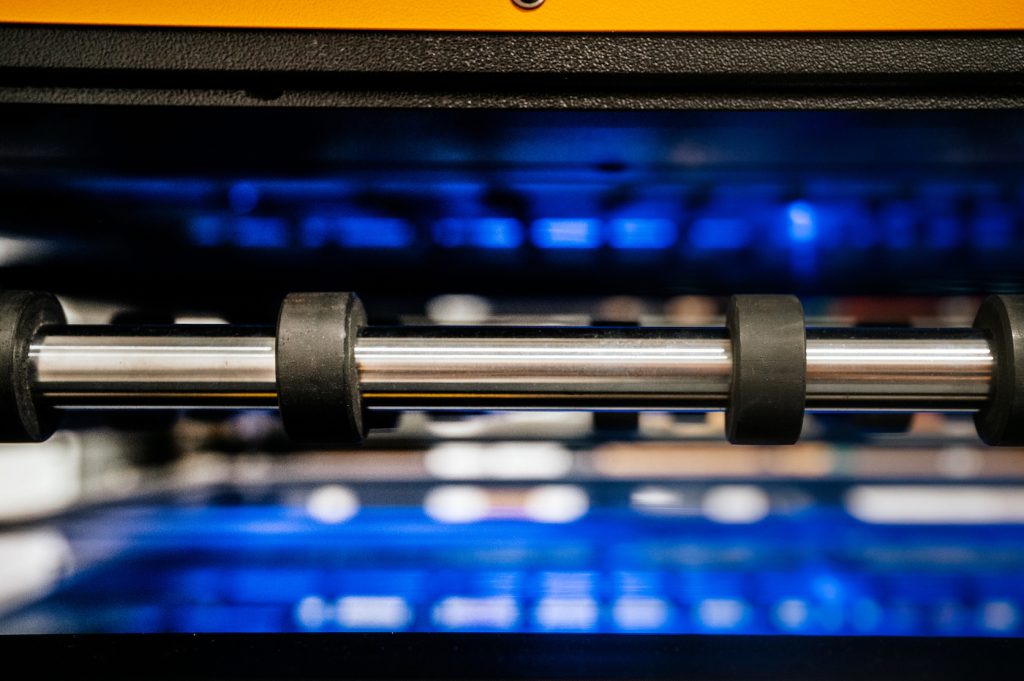

The DIMX system is a fully automated inline dimensional measurement metrology system for flat glass panels providing measurements for 100% of production runs. The DIMX system will sustain full continuous production speed with a cycle time of 4.5 seconds and measurement repeatability of 0.1 mm at 3σ with an accuracy of 0.1 mm. It has been designed for a wide range of glass manufacturing applications, including automotive, appliance and architectural glass. And the DIMX system can be integrated to existing production lines in which SURFX or EDGE line of products are already installed.

The DIMX system measures the following glass characteristics:

- Hole size

- Hole position

- Hole roundness

- Hole to hole distance

- Hole to edge distance

- Panel size measurement

The glass can be of any shape and size within specifications and enter the system in any orientation.

As with all SYNERGX products, the DIMX can be complemented with Industry 4.0 real-time access to inspection result data, a remote operator inspection display terminal and an interface to your PLC controller.

These features make the DIMX system fully integrated, versatile, and capable of providing the measurements you need for your specific applications and requirements.

So say goodbye to limited manual sample measurements and take advantage of a completely automated measurement system for all your glasses.

Do you want to learn more? Watch our video here