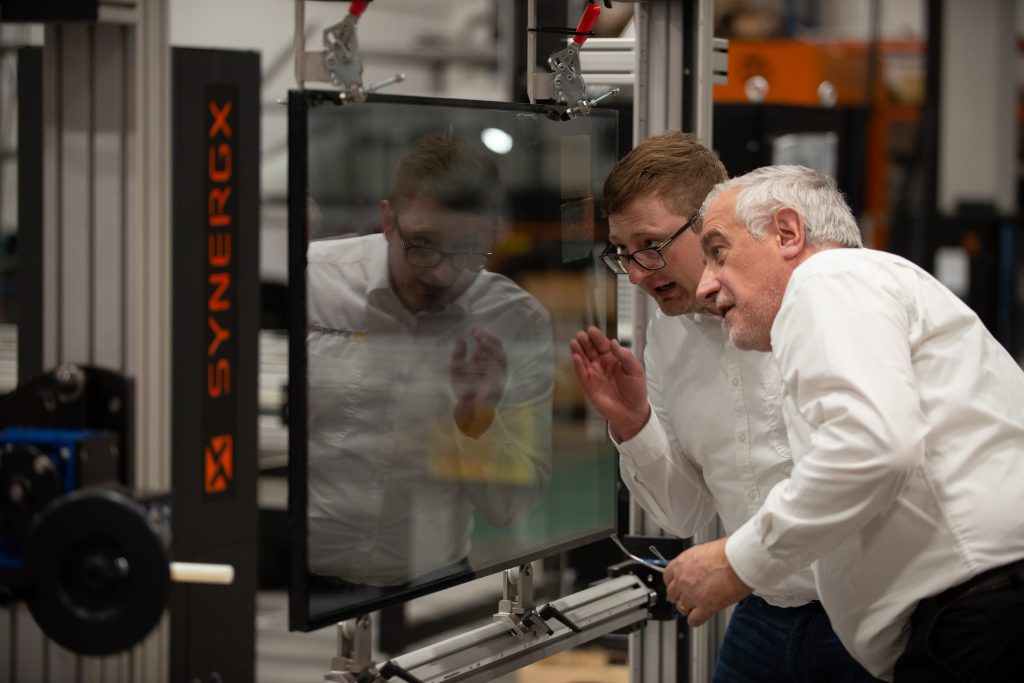

SYNERGX's Testing Facilities

Test & learn from your glass samples. For OEMs & their customers.

Better compliance with regulations

Glass inspection standards are becoming increasingly high and complex, requiring in-house advanced glass inspection validation systems. In a tight labor market and with increased demand for high quality glass, automotive glass manufacturers are struggling to ensure the level of product quality required to meet industry standards and customer specifications.

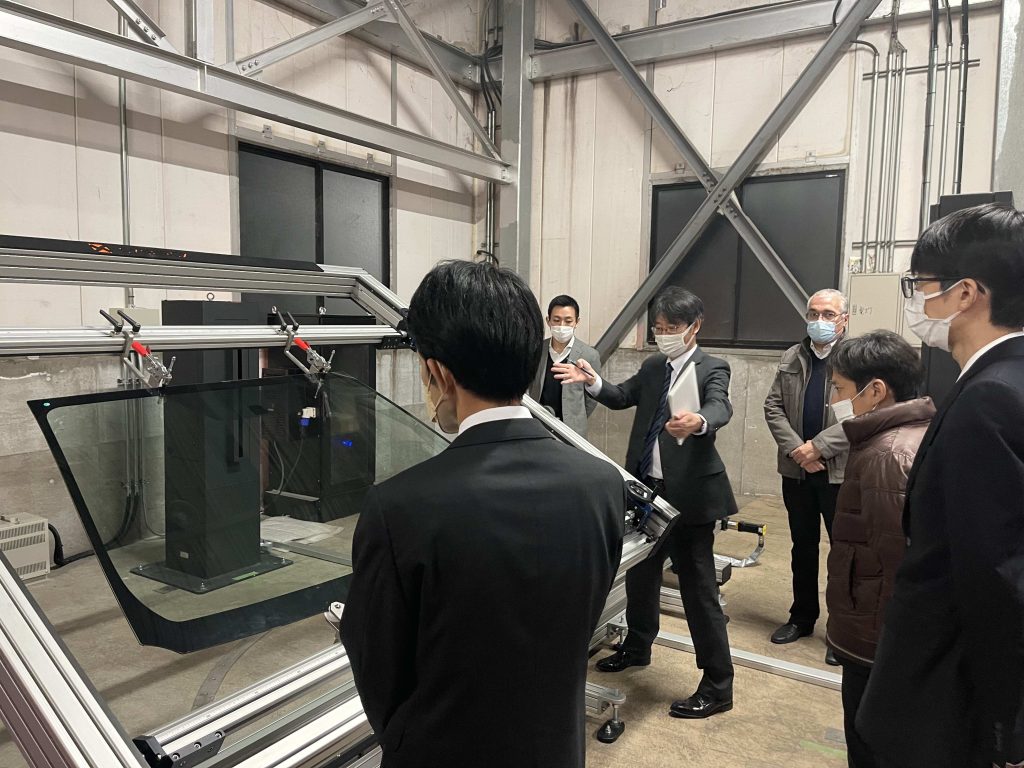

To respond to this reality, SYNERGX has set up 5 glass quality control facilities available all around the world. These state-of-the-art labs offer glass manufacturers an efficient and reliable way to test, validate and improve their glass quality—without overburdening their staff or current production workflows.

SYNERGX LABS

SYNERGX LABS offers the service to evaluate and characterize the optical properties of automotive glazing.

Our lab facilities have been designed to inspect both new product development initiatives and production samples to determine if they meet the industry’s ever-evolving standards for automotive glass.

Our SYNERGX LABS services are available in 5 locations worldwide.

Benefits

Validation

Validate products using standardized and repeatable test protocols to ensure result integrity

Expertise

Access to responsive experts in automotive glass optics

Measure

Rely on the most up-to-date measuring tools based on advancements and best practices in the automotive glass industry

Evaluation

Evaluate quality performance over time for key suppliers

Process

Implement custom processing plugins to meet specific glass inspection needs